The grind has begun!

After negotiating a number of technical, weather-related and manpower setbacks, SDSU’s Break the Ice Lunar Challenge team began grinding concrete at 8:30 a.m. Monday, July 31, in the NASA contest.

SDSU was one of 15 groups nationwide selected as a finalist to grind and deliver 800 kilograms (1,760 pounds) of concrete daily for 15 consecutive days. A variety of cameras are continuously recording the operation so NASA can verify the work, which must be done autonomously.

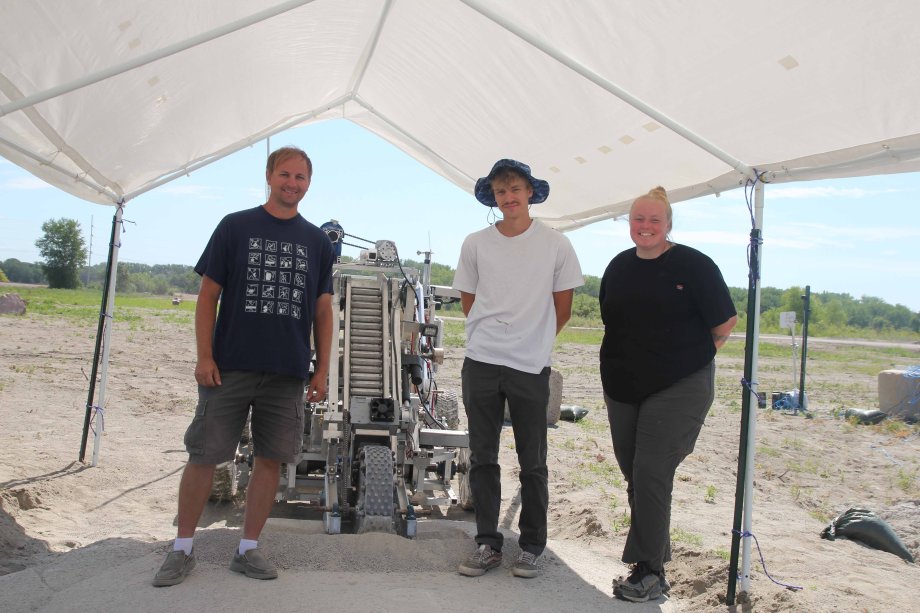

Pictured, from left, are associate professor Todd Letcher, incoming senior Carter Waggoner, of Rapid City; and incoming graduate student Allea Klauenberg, of Ogden, Iowa. The team consisted of 14 undergraduate students, one graduate student and one recent alumni when it was tabbed Dec. 14, 2022, by NASA to compete against teams from India, the Netherlands, Redwire Space, a publicly traded corporation; several small space start-up companies and a couple university qualifiers.

With most of the crew now gone from Brookings and starting new careers, Klauenberg, Waggoner and Eric Derr, an electrical engineering major from Sioux Falls, have been the “gold medal” performers, Letcher said.

He also lauded the work of Jason Sternhagen, research associate III and co-leader of the project, for his summer commitment making Space Trajectory a functioning operation.

The concrete, a weaker version of what one would encounter on a roadway, replicates regolith, the hard, icy substance found in the coldest, darkest places on the lunar surface.

Shown behind the trio is the project’s excavator, which was built in the college’s production lab out of heavy grade aluminum. The teeth on surface and side of the excavator wheel creates the concrete powder, which is deposited into the conveyor. The “lunar soil” lands in a holding bin. When full, the bin is emptied into a battery-powered dump truck for delivery to a site one-third of a mile away.

All equipment is operated autonomously. Should it break down during the 15-day testing period, the team can’t continue to compete, Letcher said. All teams must have their detailed final reports and videos to NASA by early October, but the SDSU team, which bills itself as Space Trajectory, wanted to have testing work done prior to the start of fall classes Aug. 21.

- Contact:

- Telephone number: 605-688-4538

Republishing

You may republish SDSU News Center articles for free, online or in print. Questions? Contact us at sdsu.news@sdstate.edu or 605-688-6161.