Senior Design Capstone Program

Agricultural and Biosystems Engineering (ABE) applies the science of engineering to products and processes of the agricultural industry. Senior ABE students participate in a two-semester applied-design project course completed in conjunction with industry sponsors. The program allows students to apply their education and to experience the dynamics of an industry-based project. Through the Capstone Program, the ABE Department aims to produce excellent graduates that are equipped with the knowledge, experience and applicable skills to handle modern-day challenges in the industry.

Project Timelines

First Semester:

- Student teams are matched with a project sponsor

- Development of project charter

- Application of ideation process to form concepts

Second Semester:

- Execution of project plan and analysis of concepts

- Production of a physical prototype or mock-up

- Formal project write-up and group presentation

For more information about the Senior Design Capstone Program, please contact Douglas Prairie.

Interested in being a sponsor? Visit our For Our Sponsors page to learn more.

Past Projects

Project Title: Mushroom Culter Shed

Presenter Names: Justin Taylor, Matthew Elgert

Sponsor: Joseph Darrington

Acquiring fresh produce has always been an issue. It has taken years of genetic engineering and selective breeding to get produce to the point where it is sellable in stores. Still, there is a large quantity of waste. Because of this, many people have turned to home gardens. The same logic applies to mushrooms. However, there is not an alternative to buying mushrooms at the grocery store like there is with fruits and vegetables. Our goal is to create a structure that can provide this alternative. This structure will be a shed. It needs to be able to grow roughly twenty pounds of mushrooms per week. The shed will have a temperature control system that will allow it to be ran during any season. This will consist of a cooling system and heating system. Mushrooms also require different moisture requirements than plants. Mushrooms need moisture and humidity in the air, so the shed will need a moisture control system as well. The moisture control and temperature control will be the most difficult and complex aspect of the project. The moisture control has its own unique set of challenges. Moisture inside the structure means that any exposed wood will need to be treated to prevent rotting. The temperature control system will also be a major challenge. Here in South Dakota, we get an extremely wide range of temperatures. The goal of the project is to be profitable. We have to be mindful of how much energy gets put into the environmental controls in order to keep costs down.

Project Title: Electric UTV

Presenter Names: Paul Schlotman (ABE), Rian Byers (ABE), Kade Griesse (EE), Kaden Karst (EE)

Sponsor: Dakota Lakes Research Farm – Sam Ireland, Dwayne Beck

The Dakota Lakes Research Farm Corporation is a not-for-profit entity near Pierre, South Dakota. The farm is made up of farmers/owners and managed by the Board of Directors. Dakota Lakes Research Farm is in the process of designing and installing a solar array to supply electricity to the zero-net-energy building and the grain bins site. This is a step towards a long-term goal of fossil fuel neutrality for the farm. Excess electricity can be sold back on to the grid at a reduced price to that at which it would be purchased from the REA. It would be more economical and efficient to utilize all the electricity produced from the solar array. Electrifying farm vehicles is a goal for the farm. Our project focuses on electrifying a gas powered UTV. The selected UTV is a 2004 Polaris Ranger that was acquired from Dakota Lakes. The project involves removing all the internal combustion engine and unnecessary components like the gas tank, oil tank, and radiator. Electric components including batteries and the motor will be chosen based on the given use case specifications which include: top speed of 30 mph, tow 1500 pounds, 20 mile range, and recharge in under 8 hours. The UTV will be used on a farm, so it will be designed for harsh environments and versatile use. Auxiliary power in the form of a 110V plug and other power capabilities are being considered in the UTV design. This project helps the research farm meet their goal of fossil fuel neutrality and shows electric solution to farmers for their on farm UTVs. Electrification will help reduce overall power use and pollution of a combustion engine with no idle time.

Project Title: Friesen Cylinder

Presenter Names: Jacob Kleven and Jake Thompson

Sponsor: Lee Friesen

Lee Friesen is an entrepreneur from Olivet, SD that is continuously looking for ways to improve current products in a way that haven’t been considered yet. Lee saw potential in changing how fluid is supplied to auxiliary hydraulics at the end of a cylinder, specifically in the telehandler market. Traditionally, the way this hydraulic fluid is supplied to the auxiliary components is through the use of flexible rubber hoses. These hoses move with the cylinder as it extends by means of a hose chain or pulley system. As the cylinder extends, the hose chain or pulley system operates in a way that allows for more of the rubber hose to be released to follow the extension said cylinder. One main issue with this current design is that hoses rub on surfaces, like pulleys, wears them down until they eventually need replacing due to failure. Lee proposed a solution of replacing the hose chain or pulley assembly, along with the hoses themselves, with a mechanism that follows the extraction and retraction of the cylinder in a telescoping way. This new telescoping feature would remove the issue of hoses wearing down over time and replace it with a metal tube that extends and retracts with the cylinder. This new design would be a viable option to be used for both new manufacturing and retrofitting to current products. This design will also include plates that allow for the telescoping tubes to connect with the cylinder so that as the cylinder extends, the tubes will follow suit. Proof of concept of this design will be completed by using a small cylinder along with our newly designed parts to demonstrate how the product would function.

Project Title: SDSU Cottonwood Field Station Feedlot

Presenter Names: Amelia Brandenburger and Lena Ouandaogo

Sponsor: NRCS

The NRCS (National Resource Conservation Service) is a government agency that works with farmers, private landowners, and managers to help protect the natural resources in their specific area. The South Dakota State University Cottonwood Field Station Feedlot is in Phillip, SD and consists of roughly 2600 acres. This land is used to facilitate research for the university such as crop and soils, weather, and cow-calf pairs. As of now, the feedlot is rundown and has tons of manure draining into the local waterways. Our focus in concurrence with the NRCS is to design and implement an updated wastewater management system to eliminate the amount of runoff the research station is producing. Currently the feedlot has 12 pens for the cattle, but not all are usable due to extreme flooding and no drainage path. With regulations from the NRCS we are fully designing a new barn and management system that is outside of the 100-year flood region, which they currently are in. Our goal is to design a couple of possible designs for the feedlot management system layout while also keeping in mind the possible design of the actual barn. The actual design of the new barn is being outsourced to a consulting firm from South Dakota and surrounding states. As of now we have decided to use a VTA, vegetative treatment area, as the main management system that will be implemented. After speaking with our NRCS representative, the station manager, and the voting board they will choose which design they would like to go with and continue the design work. Some of the things we have to keep in mind is the flowability of the set-up, feasibility for the station manager, the amount of maintenance the system would need, and the overall cost it would take for the complete project.

Project Title: Silver Creek Dam Rehab

Project Presenter Names: Josh Becker and Ethan Tellinghuisen

Sponsor: NRCS

The Silver Creek Detention Dam I is an important structure, controlling the flow of water from nearly a 900-acre watershed area. This dam was constructed near Baltic, South Dakota over 50 years ago. It was constructed with an outlet pipe that has two different sections. The upstream section is reinforced concrete pipe and the downstream section is corrugated metal pipe. The corrugated metal pipe has since begun to rust out and has caused internal erosion to the embankment. If degradation of the integrity of the dam continues at the projected pace, internal failure of the dam is imminent, and action must be taken now to repair the dam to reliable condition before a catastrophic event occurs. In the event of total dam failure, there is potential for millions of dollars in total cost of agriculture destruction, property damage, and entire dam repair. Clearly, steps must be taken to avoid this event. A team of Agricultural and Biosystems Engineers at SDSU have stepped up alongside the Natural Resource Conservation Service to devise the most cost-effective solution to this urgent problem. We have narrowed down our concepts to two options. Those options are to replace just the problematic pipe section or to place a pipe liner through the existing pipes. After extensive research and design, construction plans will be presented at the end of the 2022-23 academic year, from which the appropriate measures can be taken to fully repair the dam. The process of creating the construction plans will be meticulously completed, ultimately resulting in a well-organized, efficient construction project. Silver Creek Detention Dam I will be restored to full strength and function by the end of summer 2023, weather permitting, ensuring protection of the surrounding homesteads and agriculture.

Project Title: SDSU Sweeper

Presenter Names: Marcella Reese and Anna Prchal

Sponsor: SDSU Facilities and Office of Sustainability

This project is focused on replacing the current plastic bristles on the skid-loader angle broom brush with a sustainable biomaterial. Currently on campus, the sweeper is used to remove snow, dirt, and debris. The bristles often break off, leaving plastic pieces behind, and wear down, resulting in released microplastics. By replacing the bristles with a biodegradable biomaterial, the risk of environmental damage could be reduced. The scope of the project is focused on creating a material that is sustainable to produce and use while remaining functional. Currently, the project is progressing towards using bioplastics combined with finely ground biomaterials that are locally sourced from byproducts including crop and lumber production. The materials (corn, soy, wheat, and wood) are selected using a decision matrix to determine the best options to be used as an alternative for the current plastic design. A scaled down model will be used to test functionality, wear, and durability based on the force applied. To test the different materials, the bioplastic and biomaterial combination will be placed in a mold to create universal standard testing specimens. The new bristles will undergo a series of tests to evaluate the feasibility of being used on a large scale. The durability and wearability will be determined by simulating the sweeping motion on concrete, which is the main surface the brush is used on. The apparatus will be placed on a hand drill with the force and RPMs to scale while the bristle wear is recorded. The biomaterial’s strength will be tested using a texture analyzer to determine the deflection, yield point, and fracture point. To simulate weather conditions, the biomaterials will be soaked in water and placed in cold conditions prior to repeating tests. The test results will show if the biomaterials are a realistic and functional alternative.

Project Title: Cover Crop Seeder

Presenter Names: Levi Sorensen, Brady Nelson

Sponsor: Ali Mirzakhani and Agronomy, Horticulture and Plant Science Department

Farmers spend thousands of dollars every year applying fertilizer and cover crop seeds to their fields. Right now, there isn’t equipment on the market that has the capability of applying cover crop seed and fertilizer within the same field pass. With the price of everything on the rise, farmers are also looking for ways to reduce their input costs. Our project is designing a tool that seeds the cover crops and delivers fertilizer to the plant at the proper timing to maximize the yield potential. Being able to apply fertilizer and cover crops at the same time would also eliminate a pass through the field and this would help reduce input cost for the farmer, saving them money. The primary drawback to this project is the timing for applying fertilizer and spreading the cover crop seed do not happen at the same time so we need to find a way to be able to delay one of the applications, so the timing all works out. Another drawback is there are different ways to apply fertilizer along with it coming in different forms so depending on the form of the fertilizer the farmers use will change the design that needs to be used. The last drawback comes in the delivery form, we think that if we would put the seed and the fertilizer in the same trench as the seed that it would kill the seed or best-case scenario it would take some of the fertilizer from the crop.

Project Title: Hydraulic Steering Trainer

Presenter Names: Craig Santema, James Kellen

Sponsor: Raven, Danfoss and Agricultural and Biosystems Engineering Department

The Agricultural and Biosystems Engineering, Agricultural Systems Technology, and Precision Agriculture programs at South Dakota State University are known for educating students to help feed the growing population. The current facilities allow for instruction of basic hydraulic systems, but not the specific inner workings of a hydraulic steering systems. The objective of this project is to design and construct a hydraulic steering trainer for the Raven Precision Agriculture Center. The plan for the project is to have a trainer with the hydraulic steering system of a modern tractor. We will accomplish this using a steering motor, pump, EHI valve, steering cylinder, and other supporting parts of a hydraulic system. Ideally, this trainer will be able to be wheeled through a standard doorway, plugged into a 110-volt outlet, and turned on. Raven and Danfoss are assisting with this project by providing parts, advice, and industry knowledge. The steering trainer will be able to be run off either its own pump system or an auxiliary pump. The steering trainer will need a 110-volt power supply to power the on-board pump and the Raven monitor. The steering trainer will be able to teach steering by turning a steering wheel or demonstrate how autosteer works using the Raven monitor and valve.

Project Title: Quarter Scale Tractor IVT

Presenter Names: Brenden Fredrickson, Levi Wicks, Nicholas Krantz, Alex Romer

Sponsor: SDSU Quarter Scale Tractor Club

The SDSU Quarter Scale team has been one of the largest contenders in the annual competition year after year. Because of the constant innovation within the agriculture sector, the mechanics of tractors are constantly changing to improve their efficiency and power. One of the largest changes in recent years has been the transition to infinitely variable transmissions (IVT’s). By using an IVT, a pulling machine is able to maintain its mechanical efficiency in a pulling competition and improve its cruising speeds in a driving scenario. This can be achieved through the use of the planetary gear set being locked out when pulling and then being powered by an auxiliary hydraulic motor when faster drive speeds are necessary. The gear ratios and drive speeds have been confirmed by last year’s team, however there are still many challenges at hand. The largest challenge is scaling down this transmission to ¼ scale tractor size and being able to pack all of the necessary components into a solid and reliable housing that will fit within the tractor. After the design phase is complete, the final parts will be ordered for assembly. Once assembled, the gear set will be tested, and data will be recorded involving the drive speeds and temperatures of the system. If confirmed to be a reliable option to be implemented into the SDSU Quarter Scale Tractor after testing, then the team will work with the Quarter Scale team to implement for the competition.

Project Title: Fluid Power Vehicle

Presenter Names: Dalton VanderWal, Dylan Hanisch, Ethan Geraets, Cole Shannon, Patrick Lovrien, Bret Barnett

Sponsor: NFPA and SDSU Fluid Power Club

The National Fluid Power Association (NFPA) is an organization that was founded in 1953. The focus of this national group is exclusively towards fluid power technology. Every year, they put on a fluid powered vehicle design competition. This competition consists of utilizing a hydraulic circuit to propel a bike pedaled by a human. For this competition, you are judged on multiple various categories; overall, best presentation, sprint race, efficiency, endurance, design, reliability, and safety. Teams from different colleges across the country compete to design the most efficient fluid powered vehicle. Our objective for this project is to create a bike that is simple in design, durable, and efficient. We are the second team that SDSU (South Dakota State University) has had participate in this competition. Because of this, we have the benefit of utilizing the previous team's vehicle and data. We need to get the bike running so that we can collect some more data to determine which components need the most improvement. Once that data is collected, we can begin to build our circuits and order necessary parts. After the vehicle is built there will be multiple testing trials. In between those trials, we will go back and find solutions to better improve the vehicles efficiency. Once we are satisfied with our testing results, we will go to competition and present in front of the competition judges.

Project Title: SDSU Cottonwood Field Station Feedlot

Presenter Names: Molly Rick, Megan Bodin

Sponsor: NRCS

The South Dakota State University Cottonwood Field Station was established in 1907. Originally focused on soil and crops, cattle were later added to the research program. Their current feedlot is in poor condition and needs updated and redesigned. The NRCS was assigned the project and thought it would be a good senior design project. The NRCS is a government agency that stands for Natural Resource Conservation Service. They assist private landowners in conserving soil, water, and other natural resources. The current feedlot has 12 pens of which only 8 pens are usable. Most of the fencing is broken and unusable. They have no current wastewater management system. The project scope is to design a new feedlot layout that has a wastewater management system to control the runoff water from the feedlot. They are looking to remove all existing fences and replace them with all new fencing. We will produce at least two possible designs for the feedlot layout and two possible designs for the wastewater management systems. The two unique designs for the wastewater management system will be a holding pond or a vegetative treatment area. Working side by side with an NRCS representative, the station manager, and the lead research role, we will offer two layouts for the overall feedlot to go with our wastewater management system. We will keep in mind things like snow removal and drovers alleys to ultimately achieve the most effective way to get the cattle to the chute.

Project Title: AGCO Dry Spreader Rate Sensor Phase II

Presenter Names: Tanner Rupp, Issac Fordahl

Sponsor: AGCO

AGCO is one of the leading global manufacturers of agricultural equipment and implements with a strong presence in the chemical application market. Currently, AGCO offers a product flow rate sensing system for their granular fertilizer spreaders that consists of a Dickey-John sensor which outputs the linear speed of a belt chain carrying the granular product from a hopper by converting the rotational speed of a hydraulic drive motor to calculate the tangential speed of the drive sprocket. The product carried from the hopper by the belt chain discharges through a rectangular cross-section gate before being distributed to either a rotary or pneumatic conveyance system depending on the configuration of the machine. Assuming that the product cross-section is the same as the gate cross-section, the mass flow of product can be determined using the speed calculated by the Dickey-John sensor, cross-sectional profile of the product, and the density of the product. The primary drawback to this rate sensing system is that it lacks the ability to directly measure product flow rate as it does not interface directly with the product. In addition, the current system is incapable of detecting conditions of no product flow due to a backup at the gate, the bin running empty, or the chain breaking since the only measurement taken by the current sensor is the rotary speed of the hydraulic drive motor which will continue to rotate regardless of whether or not product is flowing. To address the shortcomings of the current rate sensing system, a method of direct mass flow sensing is to be determined. This will be accomplished using the scaled down test bed constructed in Phase 1 to replicate AGCO’s granular spreader to test several sensor options to determine which option produces optimal mass flow readings. Current sensor options include a rotary fin sensor and a strain gauge setup.

Project Title: Lake Mitchell Water Quality

Presenter Names: Wyatt Ewing and Logan Kolb

Sponsor: City of Mitchell

Lake Mitchell of Mitchell, SD is a 700+-acre lake created in 1928 on Firesteel Creek to be used as the primary water source for the city. Today, it is no longer used as a potable water source at all, and recently recreational activity has also seen a decline due to water quality issues. Both Firesteel Creek and Lake Mitchell are listed on the State’s list of “impaired water bodies”. The project scope involves assisting the city in designing a floating vegetation island system that will be used to filter elements such as potassium and phosphorus from the water system. Two options being considered include floating islands installed at the inlet of the lake with the second involving an earthen jetty which would create a smaller inlet into the primary body of Lake Mitchell. The project will look at the cost impacts of both designs and provide proposals to the city of Mitchell for their consideration.

Project Title: SDSU Portable Fly Trap

Team Members: Ross Hoefling & Garrett Dean

Project Maturity: 1st Semester

Abstract: Millions of dollars are spent every year on fly control. Traditional means of controlling insects requires owners to physically work the cattle, which adds stress on the animals. The goal of the SDSU Fly Trap is to have a natural, non-chemical, and low maintenance device to remove the flies from cattle. There are many existing designs and patents that exist for products like the SDSU Flytrap, but none of these designs are mobile and self-sufficient. The preliminary test trials this fall at SDSU’s Cow Calf unit were very productive and validated early design concepts. With the data collected on this project, ranchers and livestock owners will be able to purchase a device and place the fly trap in grazing pastures, feedlots, and diaries across the country. The process of capturing and exterminated flies can be broken down into a simple summary. Cattle with flies on them walk into the main part of the fly trap having flies being brushed off. Flies do not like the dark and with the dark tarps and dark roof the flies fly up through a false ceiling towards the light, where they are captured. The flies will be trapped and killed between the black false ceiling and the clear tarp that covers the roof. Through more design work and testing in the summer months of 2021, we believe we can have a finished product that could be marketed to farms and ranches to begin controlling insect populations on their livestock in an effective, non-chemical, and environmentally friendly fly trap

Project Title: SDSU IQS IVT Transmission

Team Members: Ty Grone, Luke Schemm and Jeremiah Dooyema

Project Sponsor: SDSU Quarter Scale Tractor Team

Abstract: The SDSU Quarter Scale Tractor team is recognized for being a top contender in the ASABE sponsored international design competition. In recent years the tractor team has been utilizing a traditional fixed gear drivetrain, however looking forward variable ratio drive appears to be the next viable step. The team has decided to sponsor a proof of concept project for an infinitely variable split-power transmission utilizing a single planetary gear set with varying ring gear speeds. The competitive nature of the competition requires each team to produce a transmission with minimal power loss. To achieve maximum pulling efficiency the primary pulling gear ratio will be designed to be operated in a fully locked out mode meaning the ring gear will be stationary in this condition. Two modes of powering the ring gear are being investigated with one being a variable speed hydrostatic drive with the second being a variable speed electric drive. The project will produce theoretical calculations, a working proof of concept along with recommendations for a full-scale prototype.

Project Title: Bobcat Auger Angle and Depth Sensor

Team Members: Alexander Masloski and Trevor Sik

Project Sponsor: Bobcat

Abstract: Bobcat is leading the industry in design, manufacturing, marketing, and distributing compact equipment worldwide. Bobcat is based out of North Dakota, where the compact equipment was invented over 60 years ago. This company currently provides many different types of machines and attachments. Bobcat has attachments for excavators, skid-steer loaders, and compact tractors. Bobcat already has a “knuckle-joint” design that assists with using an auger for drilling vertical holes on uneven ground. This joint allows the auger to swing freely with gravity so it will always start in the vertical position. For this project, an attachment for a skid steer auger is coming to life. Presently a novice operator has no indication of the augers vertical angle outside of a visual inspection. Our goal is to add a device to this auger that will display the augers present vertical alignment. The other component novice users presently struggle with is depth of the drilled hole. This piece of information is typically provided by an external spotter. A real-time on-board depth measurement device would provide the operator of the auger an estimated hole depth. These attachments will show the user real time information of the augers vertical position and depth allowing for the operator to make the necessary corrections to retain a vertical hole that is at the correct depth. In summary this device would make operating an auger more streamlined for a novice user.

AGCO Dry Spreader Rate Sensor - Scott Cowan, Jayden Waldner, Joshua Irvin

Sponsor: AGCO

Project Maturity: First Semester

AGCO is one of the leading global manufacturers of agricultural equipment and implements with a strong presence in the chemical application market. Currently, AGCO offers a product flow rate sensing system for their granular fertilizer spreaders that consists of a Dickey-John sensor, which outputs the linear speed of a belt chain carrying the granular product from a hopper by converting the rotational speed of a hydraulic drive motor to calculate the tangential speed of the drive sprocket. The product carried from the hopper by the belt chain discharges through a rectangular cross-section gate before being distributed to either a rotary or pneumatic conveyance systems depending on the configuration of the machine. Assuming that the product cross-section is the same as the gate cross-section, the mass flow of the product can be determined using the speed calculated by the Dickey-John sensor, the cross-sectional profile of the product and the density of the product. The primary drawback to this rate sensing system is that it lacks the ability to directly measure product flow rate as it does not interface directly with the product. In addition, the current system is incapable of detecting conditions of no product flow due to a backup at the gate, the bin running empty, or the chain breaking since the only measurement taken by the current sensor is the rotary speed of the hydraulic drive motor, which will continue to rotate regardless of whether or not the product is flowing. To address the shortcomings of the current rate sensing system, a method of direct mass flow sensing is to be determined. This will be accomplished by constructing a scaled-down test bed to replicate AGCO's granular spreader and test several sensor options to determine which option produces optimal mass flow readings.

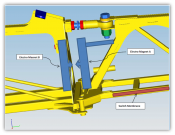

Self-propelled Sprayer Crop Protection - Michael Hansen, Tate Ketelhut

Sponsor: CNH Benson

Project Maturity: First Semester

Case New Holland is a global equipment manufacturer that produces numerous different product lines. In 1998, Case IH acquired Tyler Manufacturing, which started the patriot self-propelled sprayer line. This line is still manufactured in Benson, MN. With the current precision agriculture technologies, minimizing crop damage caused by machinery has become a concern to maximize yields. CNH offers a bolt-on wheel shield, which minimizes amount of crop that gets run over by the sprayer tires. The structural performance on the current crop shield isn't meeting the lifespan desired by CNH. The current design is also hard to manufacture and not easily removable, which is hindersome for both CNH manufacturing and the end user. CNH has requested a new design for the internal shield structure that provides increased lifespan, ease of manufacturability and toolless connection. The new design will be constructed out of formed tubing to minimize weld joints and increase manufacturability. Also, a concept for toolless disconnection will be presented to allow for ease of installation and dismount. Testing will be conducted with a patriot 4440 using similar practices to that of the current shield. Strain gauges and accelerometers will be attached to the structure, then it will be driven over a test course. The lifespan of the new shield can be calculated from our testing data. We will also be able to compare our testing data against CNH's previous data. this concept will provide CNH with an improved design that can withstand the tough conditions faced during operation. It will also offer easier installation and dismount for the operators.

Lake Mitchell Water Quality - Nick Fuhr, Blake Wolters

Sponsor: City of Mitchell

Project Maturity: First Semester

Lake Mitchell of Mitchell, SD, is a 690-plus-acre lake created in 1928 on Firesteel Creek to be used as the city's primary water source. Today, it is no longer used as a potable water source, and recreational activity has declined due to water quality issues. Both Firesteel Creek and Lake Mitchell are listed on the state's list of "impaired water bodies." The project scope is to assist the city in the design of 200-plus acres of land/waterway of Firesteel Creek to improve water quality, concerning mainly phosphorus levels. Using LiDAR data and USGS flow rates, the team will develop a system of control structures that will allow for settling of phosphorus particles in the creek before they enter the lake. As flow rate is a function of velocity and area, the addition of a control structure will provide a way to increase the area of the flow and decrease the velocity, which will stimulate more settling. Approximately 370 acres of upstream land were recently purchased by the city, along with the acquirement of a shoreline easement of Firesteel Creek with landowners. Samples from 2018 showed that the historic channel valley of the lake holds up to 7 feet of previously accumulated sediment, but it is unclear as of now if dredging or capping will be within the scope of the current project. The early concept of the project is to use a low-head dam in combination with a sluice gate further upstream to be able to raise and lower water levels to facilitate the removal of phosphorus-collecting vegetation and sediment to prevent its reentry to the system. Vegetation along the creek easement will be selected to act as a phosphorus hyperaccumulator. LiDAR and hydrologic data will be analyzed with ArcGIS at various flow rate scenarios.

Vermeer Powered Windguard - Bennett Peterson, Jacob Filk

Sponsor: Vermeer Corporation

Project Maturity: Second Semester

Vermeer Corporation is an international manufacturing company based out of Pella, IA, that focuses on niche markets. Vermeer has a very extensive forage division that provides high-quality products ranging from cutting and conditioning to baling crops, which include grass, straw and cornstalks. The forage division offers a Corn Stalk Special baler to maximize productivity in hard-to-bale crops. The pickup, windguard and main frame interaction have changed substantially from the old model and do not allow for the old powered windguard to be installed in the baler. Major challenges with the new design will be achieving proper interaction of the powered windguard and crop while not interfering with the new windguard and pickup operation. The Corn Stalk Special baler has been offered for several models of balers and it is important to continue offering this option to customers for increased productivity. The new design must achieve a throughput of 80 bales/hour, be comparable in cost for sale in an aftermarket kit option and be easily removable. Two unique designs will be developed and tested, then a recommendation will be given to Vermeer in December 2019. These designs will be created in SolidWorks in order to provide a final proof of concept for Vermeer that they can easily modify into a production-level final design.

Load King Active Gooseneck Control System - Jason Brenden, Nick Carroll and Ben Schroeder

Sponsor: Load King Trailers

Load King is a leading manufacturer of custom heavy-haul trailers. The Load King Signature Series (SS) is a detachable gooseneck trailer. The gooseneck detaches from the deck of the trailer to allow heavy machinery to load directly onto the deck. The gooseneck remains attached to the truck and is supported by a hydraulic frame lift that rests on the truck frame. Detaching the gooseneck from the deck currently requires the operator to leave the truck and operate controls for a self-contained pony motor, hydraulic/ pneumatic cylinders, and a manual lock/ratchet. The detach operation is a multi-staged process that must be done in the correct order. Missed steps in this procedure typically result in damage to the frame-lift structure, ratchet structure and other components of the trailer.

In order to increase the ease of use and to prevent operator misuse, Load King would like to automate some (or all) of the steps required to detach and reattached the gooseneck. Load King would like to have an automated systems that 1) is safe, both for the operator and trailer structure, 2) is easy to use and install, 3) is minimally invasive to the existing structure of the trailer, and possibly capable of retrofitting to SS trailers currently in the field, and 4) can monitor and record system information for warranty purposes and future design reference. Sensors, valves and an onboard control unit will be added to the trailer. Plans for a phone app will allow the operator to remain in the truck while the new systems automates the hydraulic, pneumatic and manual operations for the detach/ reattach process.

Pneumatic Conveyance Valve - Shelby Wrage and Brady Gomer

Sponsor: Thor Manufacturing

Thor Manufacturing is a company out of Winnipeg, Canada, with two main product focuses: custom manufacturing and grain handling. Thor Mfg. has introduced a pneumatic grain handling system that uses air to gently transport grain (corn, soybeans, canola, etc.) to and from grain bins and trucks for small and medium-sized grain farms. The project scope for Thor Manufacturing involves the design of a pneumatic conveyor valve that can withstand <15 psi pressure while maintaining a perfect seal so no pressure or grain is lost. Possible industrial applications may be pursued if the final design meets industrial durability requirements. The final design of the valve will need to support both manual and automated control features. Automation will be achieved by a single linear actuator installed on the valve, which can be controlled via remote service panel. This project is a Phase II effort for the SDSU ABE department, and will focus on optimizing the design of the valve for manufacturability, durability and cost optimization.

Diamond Z Mower Controls Project - Devon Lammers and Nawaf Alkahtan

Sponsor: Brian Burge

Diamond Z Mowers is a Sioux Falls, South Dakota-based company that designs and produces industrial-grade roadside and brush-style mowers. Diamond Z currently utilizes a traditional joystick mounted inside of the vehicle near the operators' seat to control their mowers. This project involves a dramatic redesign on this control mechanism with a goal of improving functionality, reduction of packaging constraints, and a reduction in production costs. The current project path involves evaluating the usage of a Nintendo Switch game controller as the primary operator interface. This piece of hardware would meet the project goals while also providing wireless connectivity via its Bluetooth communication channel. Challenges will be interfacing the device within an industrial control environment and interfacing its Bluetooth communications with commercial hydraulic controls.

Electromagnetic Boom Breakaway - Tia Muller and Michael Schultz

Sponsor: AGCO

AGCO Corporation is a global agricultural equipment company with numerous brand and product lines. Recognizable brand names include Massey Ferguson, Fendt and Challenger. Challenger is an industry leader in application equipment with their RoGator self-propelled sprayers. Sprayer booms ranging from 90-120 feet are available for these machines. In order to prevent machine damage, a boom-tip breakaway mechanism allows the outer 15 feet of the boom to hinge backward when an impact occurs. The current hinge and recoil design requires a chain, spring and pulley mechanism. The design is costly and hindersome to assemble for AGCO, while being tedious to adjust for the operator.

AGCO has requested that a bi-directional hinge and electromagnetic breakaway connection be designed for their 120-foot boom and tested to establish voltage to force curves for further development of this concept. The mechanism will allow breakaway in both directions, withstand G-forces at the boom tip while turning, and maintain connection during application until an impact triggers the magnetic release. A switch membrane will be located on the bottom tip section, allowing for the impact of an obstruction to shut the magnet off and allow the boom to break away. Testing will be completed using a procedure similar to AGCO field tests. The mechanism will be enabled while a force is applied at the boom-tip and the final breakaway force will be recorded for each voltage. This research will give AGCO a baseline for electromagnetic breakaway capabilities and will allow future development of software-controlled breakaway-resistance adjustment, in comparison to the current mechanical adjustment.

Jack Wrap-It Phase Two - Matthew Cole and Brian Boese

Sponsor: Amanda Konechne

Jack Wrap-It Phase Two is a continuation project brought to the Department of Agricultural Engineering to perform research on edible net wrap. Current statistics show that 15 percent of cattle deaths in the Midwest are due to plastic net wrap accumulation in their digestive systems. These deaths result in loss of revenue for farmers and ranchers throughout the nation. An effective solution to this problem would be an edible net wrap that is digestible within a cow's rumen, has microbial resistance and won't degrade due to UV exposure. There are a few biomaterial candidates that are identified and currently produced from other agricultural fields.

The biomaterials that presented the most durability when undergoing the tensile strength test were sisal, hemp and coconut. Currently, the focus will be on hemp and a new biomaterial that has been deemed worthy due to its fiber characteristics -- flax. These materials will be tested for shelf life, tensile strength and bale life. This will be done by coating or infusing the materials with various components to increase the tensile strength and reduce microbial growth. A UV light will also be utilized to test the durability of the biomaterials to simulate exposure to sunlight after long periods of time. All biomaterials will be assessed based upon experimental performance, accessibility and cost. The goal is to find a material and then design a coating/ binding process for an edible net wrap that can be manufactured and sold to ranchers and farmers throughout the Midwest, while competitively priced with conventional materials. The development of an edible net wrap will benefit ranchers and farmers through healthier livestock.

NRCS Beef Feedlot - Jordan Beck, Nathan Benson and Gabi Ziese

Sponsor: Natural Resources Conservation Service

The Natural Resources Conservation Service, NRCS, is a government agency focused on assisting farmers and ranchers to better their operations by implementing conservation practices. These conservation practices include design of open feedlot systems to contain the runoff from these operations. Agricultural waste from these feeding operations is detrimental to the surrounding environment, so the design of a containment system is necessary to prevent runoff from occurring at these locations. The NRCS Beef Feedlot Project is based on a site about 10 miles south of Brookings, South Dakota, on an existing cattle operation. The producer wants to expand his operation to have an open feedlot designed for 999 head of beef cattle, which eliminates the need to have the site permitted by the South Dakota Department of Environment and Natural Resources.

The design of the feedlot operation requires a site survey and aerial imagery of the projected location. The lots will be sized based on the number of cattle, which then factors into the determinations of the size of the storage pond and sediment basin. Along with these structures, the layout of a feed road and feed bunk system is required for complete design of the operation. The layout of the open feedlot system will be designed to use the natural topography of the land, so the runoff from the feedlots runs downhill to the sediment basin and storage pond. The design of the system will require the use of AutoCAD and ArcGIS Software to determine the watershed and lay out the feedlots. NRCS design tools will be used to size the storage pond and develop a cost estimate for the project. The planned construction of the feedlot will be the summer of 2019 after an agreement on layout and cost is reached with the producer.

Testing and Validation of Raven’s Direct Injection Pump System - Matthew Fritzke, Chandler Jansen

Sponsor:Raven Industries

The design team partnered with Raven Industries to improve the performance and accuracy of Raven’s direct injection pump system. Raven Industries is based in Sioux Falls, SD, and manufactures precision agriculture and flow control technologies. Fritzke and Jansen developed test procedures and corresponding test fixtures to measure the actual flow produced by the injection pump under different operating scenarios. Their work sought to improve the accuracy of applying chemicals to fields and help reduce crop damage or increased weed survival.

Feedlot Design for a One-Thousand Head Cattle Operation - Christopher Waibel, Lindsay Wallace

Sponsor: Natural Resources Conservation Service (NRCS)

Waibel and Wallace assisted with the improved design of a 1,000-head feedlot in Brule County, SD. They designed a new feedlot and containment system by the current feedlot to expand herd capacity to 2,000 heads. These must be designed within South Dakota Department of Environment and Natural Resources (SD DENR) and NRCS criteria. Waibel and Wallace are gaining valuable experience from this real-life project and are getting first-hand exposure to alternative viewpoints, design concepts, and standards and regulations.

Netwrap and Twine Densification - Cody Myers, Colin LeBrun, Grant Bose

Sponsor: POET, LLC

WINNER OF THE 2017 JEROME J. LOHR COLLEGE OF ENGINEERING - ENGINEERING EXPO

The design team assisted with the development of a new process that densifies the netwrap/twine waste stream produced at the POET LIBERTY plant. The new process needed to accommodate year-round operating conditions, accept widely varying material properties and produce a material stream capable of being pneumatically conveyed to their solid fuel boiler system. Myers and LeBrun helped to develop a less energy-intensive process that increases reliability and decreases cost associated with transporting and converting corn stover to biofuels. Making the process more affordable for POET will increase productivity and the amount of corn stover purchased from regional farmers.

Hydraulic Pump Parasitic Losses - Joshua Daum, Tyler Propst Sponsor: AGCO

AGCO is a global agricultural equipment company with a wide range of products. Notable brand lines include Challenger, Ag-Chem, Massey Ferguson and Fendt. They are also well known for the TerraGator granular spreaders and RoGator self-propelled sprayers. The project sponsored by AGCO for SDSU involves determining energy losses that occur when converting mechanical (engine) energy into fluid (hydraulic) energy. Conversion efficiency is a common concern in agricultural equipment design as a large range of implements can be powered from the vehicle’s hydraulic system. The focus of our research will be studying the effect hydraulic pumps play in contributing to parasitic energy losses. Included in this research will be the design of a test stand capable of testing common pumps utilized by AGCO. These pumps will be tested under varying conditions, such as temperature and pump speed (RPM), to showcase pump performance. The input mechanical torque will be correlated to output fluid torque using a shaft torque meter and calculations utilizing output flow and pressure. AGCO will use the findings of our research to accurately select pumps for the various equipment they design. The test stand developed within this project will provide insight on properly testing hydraulic pumps for parasitic energy losses and will likely lead to a more advanced test stand capable of testing a wider variation of pumps.

Quarter Scale Tractor Drivetrain - Joseph DeBoer, Timothy Harder, Ryan VanTassel Sponsor: Daniel Humburg

The Quarter Scale Tractor Design Team of South Dakota State University is a student led organization that designs, builds, and competes in an international competition against teams across the United States, Canada, and Israel. The team has developed the need of a more complex drivetrain in search of increasing tractive effort as well as power to ground during performance events. To achieve such a feat, the Drivetrain Capstone Project was assembled to deliver a more robust, efficient drivetrain to compete with the rising level of difficulty found in the competition. The overall scope of the design is derived from that of the previous year’s tractor, with the implementation of a two speed powershift as well as integrating a dry clutch into a belt reduction system. The reduction-clutch assembly offers the ability to reduce engine speed, as well as provide a main power disconnect for the entire tractor in one process, whereas two separate sub-systems were used in the previous design. This limits the overall weight of the system, shortens the drivetrain length, and eliminates the need for multiple shielded areas in the overall tractor design. The ultimate goal of the Quarter Scale Tractor Drivetrain Project is to create a drivetrain that features four forward gears that can be dynamically shifted between two additional gear ratios for on the fly gear reduction. This is achieved by implementing a dry-activated planetary gear set prior to the transmission. The design of this two-speed planetary power shift transmission is derived from a Farmall Torque Amplifier first developed in the early 1950’s. This allows for variable speed in each range supplied by the transmission, while in turn maximizing tractive effort without having to stop to shift between gears or activate the disconnect clutch, losing tractor power and speed.

Jack Wrap-It - Macey Zeinstra, Justin Spies Sponsor: Konechne Ranch, LLC

The Jack Wrap It project was brought to the Agricultural Engineering Department in hopes of designing a safe, edible net wrap material for livestock animals that will be able to withstand long term storage and practices associated with forage use. Development of an edible net wrap material has been proposed due to the common practice of grinding bales to feed cattle without removing the net wrap. Ground hay with plastic can build up in the early digestive tract of cattle (rumen, reticulum, and omasum) and can create severe health impacts to the animal that can result in an early death. The sponsor and design team will test digestible natural fiber materials including: hemp, sisal, crop residue, carinata, among others once identified. The materials will be researched and tested in multiple ways through mechanical and accelerated aging techniques. The following characteristics will be assessed by: availability, cost, nutrition value, single strand tensile strength, composite tensile strength, long term storability, accelerated aging and feasibility to incorporate into existing systems. All materials will be assessed based on their performance compared to existing petroleum based net wrap products. The Jack Wrap It team hopes to create a fully functional edible net wrap that can improve the health of livestock while maintaining fast forage production, acceptable storability, and labor savings during feeding for cattle producers.

Hair pinning is a major factor in the germination of seed within no-till farming practices. The Row Cleaner project’s goals were to reduce the amount of hair pinning while reducing the weight of each seeder’s row-unit attachments. The design had a maximum weight goal of 42 lbs. which is 75% less than the current industry benchmark. Design criteria was to have a durable design with no bearings running in the soil, be lighter in weight, and allow for ease of adjustment. Adjustable in this context means the system will work on 7.5 in row-spacing while also working in 10 and 15-inch row spacing configuration. Testing was conducted in wheat stubble to verify functionality of prototypes and multiple design concepts. The weight limit goal of 42 lbs. was achieved for most of our prototype concepts. The prototypes allowed us to collect data and determine functional concepts and which designs could use improvement. The most recent design is still being tested and is proving to be a very durable. The design is a success in that it has no bearings running in the soil and the row cleaner is able to quickly adjust to different row spacing’s. The data we have collected will be sent to our sponsor and will determine what conceptual design they wish to pursue.

NRCS Dam Project - Seth Haigh, Nick Klingenberg, Miranda LeBrun Sponsor: Natural Resources Conservation Service (NRCS)

The Brookings NRCS office has undertaken a project to redesign and repair a previously built dam that is currently not functioning properly. The primary issue with the dam is the principal spillway is not allowing water to flow from the dam, either due to blockage or collapse of the primary spillway pipe. As a result of this issue, the pool area stored behind the dam has grown tremendously. On several occasions the dam has had to be released through the emergency spillway. This must be repaired because the emergency spillway is earthen, and not designed to withstand repeated heavy flows. The dam was built in 1978 and over its life has accumulated sediment which has reduced the dam's water holding capacity, and has likely played a key role in the failure of the primary spillway. If the dam does fail, it could potentially damage South Dakota Highway 11, as well as erode cropland downstream from the embankment. This project will ultimately produce a functional design of a new primary and auxiliary spillway that will be proposed to the Union Creek Watershed District. This design will be compiled from information gathered from topographic surveys, soil surveys, and LIDAR data, all of which will be used to determine drainage area and site suitability for a new principal, and auxiliary spillway. Our goal for the fall semester is to have the primary and auxiliary spillways properly sized and have flow calculations done, so that the spillways can be placed in optimal positions on the landscape and drawings can be created in the spring.

NRCS Feedlot - Abby Repenning, Lucas Derdall Sponsor: Natural Resources Conservation Service (NRCS)

The Natural Resource Conservation Survey, NRCS, was contacted by a cattle producer interested in expanding his current feedlot operation. The producer hopes to build a 500-head deep pit barn along with a 1000-head open lot on his current grounds. The producer’s current land consists of farm ground around a homestead and a small creek that runs through the property. Mapping was conducted prior to the start of the project. Placement of the operation, cost estimates, and design features were all components of the project. Placement of the operation depends on the geography of the land and optimal waste containment. Optimal waste containment is an issue for this producer as there is a small creek that runs through his land, runoff from the feedlot needs to be contained so it does not contaminate the creek, a major concern of the producer and developers. The containment pit design needs to be large enough to prevent contamination of the creek and other water sources. The construction cost of the project depends on what the farmer wants to pay and what can be cost-shared. The producer will review a budget that provides minimal costs along with optional add-on costs. Lastly, the design of the project will rely on what the farmer wants and the regulations for feedlots. This project will use Excel to form a budget and AutoCAD for design work. The construction of this feedlot will take place in the summer of 2018 once the producer agrees upon the location, cost, and design of the proposed feedlot.

Netwrap Densification Phase II - Brady Buck, Alex Koepke, Caleb Lang, Mitchell Sandey Sponsor: POET, LLC

POET LLC is the leading producer of corn based ethanol in the United States and has recently launched a state of the art facility in Emmetsburg, Iowa named Project LIBERTY. This facility produces cellulosic ethanol using corn stover from both round and large square cornstalk bales. The first step in the process is to remove the netwrap or twine from the bale which produces a continuous waste stream of netwrap and plastic twine. Currently, POET runs the twine and netwrap though a large grinder that processes the material into fine pieces so it can be fed into a boiler to produce energy for the plant. Last year a senior design team from SDSU successfully produced a prototype extruder that densifies one bale’s worth of netwrap every minute. The extruder produces a densified, log-shaped product with a hardened outer shell. This year’s team is tasked with developing a system that can continuously feed the extruder with both netwrap and twine with varying amounts of biomaterial under a multitude of conditions. The biomass, netwrap and twine can be introduced into the extruder under varying levels of moisture content; varying rate of feed; varying densities of materials; and varying mixture percentages of biomass, netwrap and twine. This system must be able to stockpile material and consistently meter the flow of netwrap, twine and biomass into the extrusion cylinder to keep the machine running smoothly and reliably. The final goal of this project is to identify a form of processing that can size the extruded material into a shape suitable for blowing through the plant’s eight-inch pneumatic conveyance lines directly to their boiler.

Raven Utility Turf Steering Kit - Brett Reimer, Duane Mutziger Sponsor: Raven Industries

Raven provides guidance and steering systems for the agriculture market. As a senior design group we have taken the challenge to tap into the lawn and turf market with a precise guidance and steering system using a hydraulic flow control valve. This system will be tailored to the small utility vehicle market, which means there will be low hydraulic flow rates, a price sensitive market, and limited space for packaging. Utilizing the existing hydraulics on the utility vehicles, the bulk of the add-on auto-steer components can be concealed within the vehicle. By adding hydraulic flow control, Raven can offer a more accurate automated guidance system that is versatile to fit numerous platforms. We developed our hydraulic valve for a Kubota UTV and will be handing off a design that is ready for customer testing to Raven. To achieve optimal performance we tested multiple types of valves to compare their performance versus the current Mechanical Drive Unit or MDU. Performance evaluation was based on line acquisition and GPS heading error. Line acquisition is how well the valve can keep the vehicle on the target line and heading error is how far off the vehicle is relative to the desired heading. Installing the valves and additional equipment was the biggest challenge for the project because of how compact UTV vehicles are. Locating a spot to mount the valve was an issue because we did not want it to interfere with normal operation while also protecting it from damage. We worked closely with the Raven engineering team as they provided us technical guidance and the necessary hardware and software to optimize performance of their system within this new application.

SDSU Seed Cleaner - Les Jelsma, Kyle Kramer Sponsor: SDSU Seed Lab

Seed production is a major component of agriculture. Harvested seed will likely contain some amount of foreign contaminants such as weed seeds, other crop seeds, and inert material like stems, leaves, and dirt that will need to be separated in order to provide high-quality seed for future crop production or uniform raw material for industry. Corn, soybeans, wheat, rye, flower, and grass seeds are some of the seeds that are commonly cleaned. Separation is done based on differences in seed characteristics such as size, shape, density, surface texture, terminal velocity, color, electrical conductivity, and resilience. The SDSU plant science department currently has a large assortment of different hand sieves and a small-scale air screen machine for processing seed samples submitted to its testing lab. An air screen machine separates on the basis of seed size, shape, and density by running seeds across one or more sieves and through a stream of air. Companies offer a wide range of machine sizes ranging from large multi-sieve configurations to small single-sieve machines. Present-day small-scale machines lack certain features found on larger machines limiting their performance. Given that hand sieves are already available, a small-scale machine that utilizes hand sieves with the performance of an industrial-sized machine, would be beneficial for the SDSU seed cleaning lab. This project is sponsored by Brent Turnipseed who is a professor and manager for the SDSU Seed Testing Lab as well as the Undergraduate Teaching Coordinator for the SDSU Plant Science department.

Bin Sweep Prototype - Logan Knoshal, Joshua Fast Sponsor: Sioux Steel

Sioux Steel is a well-respected name in the commodity storage and handling market. They manufacture their products from their Sioux Falls, South Dakota, plant and distribute all across the United States. The company is working with an independent engineering firm, Brent, in designing a safer and efficient grain sweep concept. Many competing companies claim to be autonomous, but after running, these companies almost always require another manual labor pass to clean the bins fully. This bin sweep concept would theoretically eliminate the need for extra labor cleaning as well as save time, increase personal safety, and potentially decrease energy consumption. The design acts on the premise that gravity is the best use of energy and to maximize it to its fullest potential, the sweep will utilize angle of repose of the grain to its advantage. Our primary task is to complete theoretical calculations and find out the acting forces on essential parts of the sweep such as loads on the sweep, required torque to drive the sweep, and possibly the sizing of the gearbox. We then will install the prototype sweep in an eighteen feet diameter bin to see how the sweep performs. A major proof of theory to the testing of the sweep includes the sweep being able to bring the grain to the center sump to be unloaded at a rate that is comparable or more effective than a traditional grain sweep. Once the initial testing phase is completed we will then evaluate the validity of the current sweep and see what changes can be made to improve quality and effectiveness of the sweep.

Conveyair Pneumatic Valve - Seth Boerboom, Jared Neuharth Sponsor: Thor Manufacturing LTD.

Thor Manufacturing Ltd. is building a pneumatic transfer system product line using its existing positive displacement air pump and airlock products. Pneumatic diverter valves are required and will carry granular product such as grain, within an automated air stream. The typical process moves dried grain from a grain dryer to a storage bin. The grain from the dryer is introduced into the air stream via an airlock and is pushed through a piping network into a storage bin, sometimes a few hundred feet away. The pneumatic diverter valve would need to send product to another bin in the series or divert the grain up to the top of the bin being filled. The valve needs to be designed in such a way that it can be manually operated or automatically controlled from a central control panel. The blower can generate up to 15 PSI of air pressure and is constructed so it will not leak air or small grains. (E.g. canola). Typical pipe sizes will be 5” or 6” in diameter, but in the future the valve may be used within industrial applications where a 4” diameter variation would be required. Typically, pneumatic valves can be quite expensive, so we are targeting a production cost of $150 to $300 plus the components required for valve automation. The two-way valve simplifies the piping setup versus more common multi-way valve designs and reduces the amount of pipe needed for a system. Also having the option to manually or automatically control the valve gives the owner options based on the needs of their system